Home > About

The Expert in Professional Cutting Solutions

About Hon G

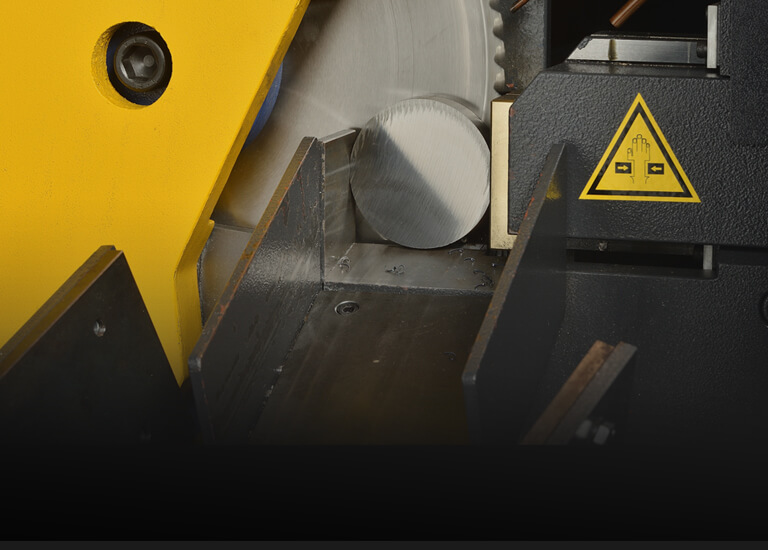

Since its establishment, Hon G has adhered to the philosophy of intelligent cutting design, developing high-efficiency and high-utilization professional circular saws and band saws.

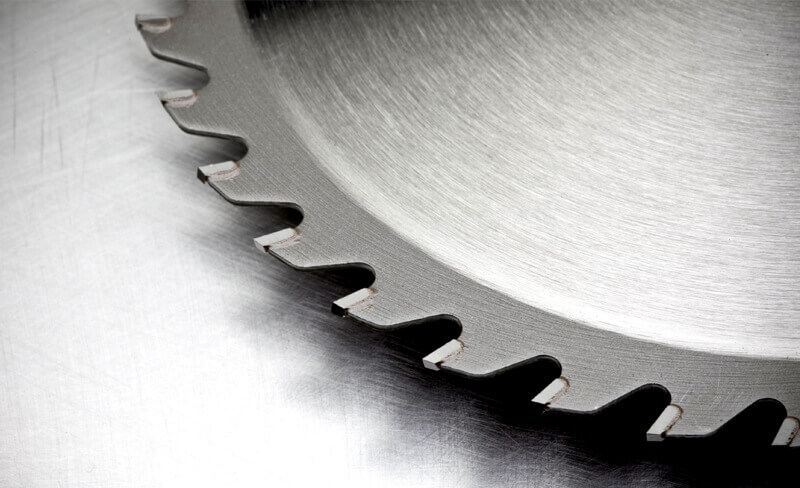

The cutting lifespan of each saw blade is 15% to 25% longer than industry standards, enabling users to cut more materials under the same conditions, significantly reducing saw blade costs for customers.

The Hon G team consists of cutting industry professionals with over 20 years of experience, including senior engineers, designers, assembly specialists, sales representatives, and procurement experts. They are well-versed in all aspects of the cutting process, whether circular saws, band saws, or cutting metal and non-metal materials.

Full-Load Cutting, Efficiency Doubled

Applications & Practices

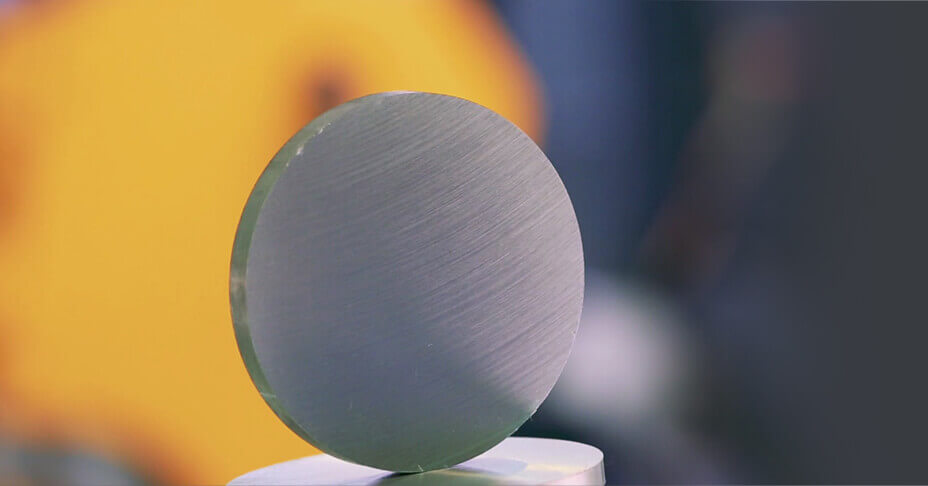

In recent years, Hon G has actively participated in construction projects within the steel and forging industries. Leveraging the exceptional cutting capabilities of its circular saws and band saws, Hon G provides precise cutting solutions for products from manufacturers in Europe, America, and Japan. These products have gained widespread acclaim from users in advanced countries.

With Hon G’s machines, after standardized calibration, even challenging materials such as stainless steel or titanium alloys can be cut with ease. The machines deliver reliable performance, enabling full-load cutting and doubling efficiency.

Ergonomic Engineering Design

Designing circular saw machines is a sophisticated art that revolves around user-centric innovation. Hon G’s engineers understand that sustainable and efficient production begins with meeting the needs of operators.

By incorporating automated systems for cutting, material handling, and collection, Hon G’s machines address both technical challenges and ergonomic concerns. These designs effectively eliminate occupational injuries, particularly to operators’ elbows, enabling employees to work in a safe and comfortable environment. This not only enhances workplace safety but also ensures seamless production while reducing labor costs.

Faster, More Accurate & Smoother

Before the advent of advanced automated cutting technology, achieving flawless steel surfaces without scratches often required companies to hire skilled operators to manually handle material feeding and collection. This not only incurred significant labor costs but also posed risks of occupational injuries over time.

To address these challenges, Hon G developed automated systems for material feeding and collection, streamlining clients’ cutting processes and standardizing operations. These innovations enable high machine utilization rates with minimal human intervention, allowing a single operator to manage multiple machines. This significantly enhances operational efficiency and increases the overall value-added per employee.

Hon G’s automation extends beyond material handling. Thoughtful features like the automatic lubrication system save clients valuable maintenance time. In the past, traditional machines without such systems often suffered damage to their transmission components due to inadequate maintenance. For businesses, machine downtime meant delayed deliveries and potential reputation losses. Hon G’s comprehensive automation designs help companies reduce costs, improve precision, and achieve smoother operations.

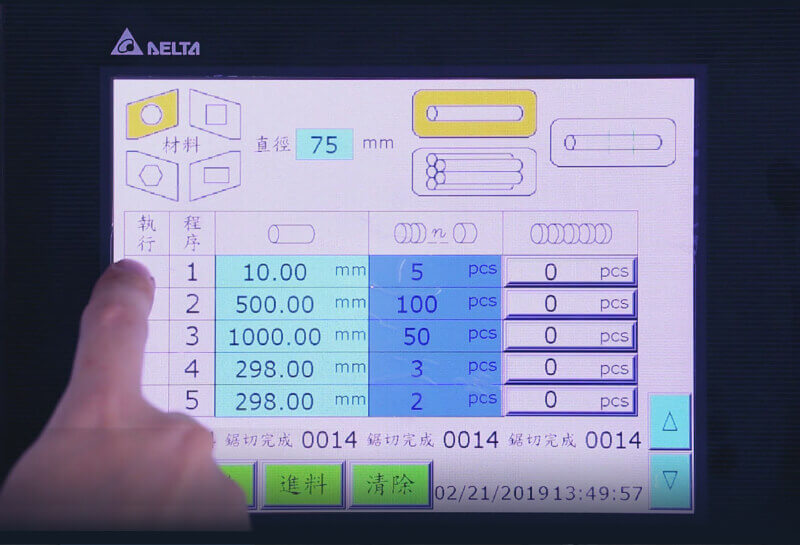

Intuitive Machine Information Integration

Hon G’s circular saw machines feature a user-friendly control panel that significantly enhances operational convenience. Users can effortlessly set cutting parameters, such as quantity and dimensions, while simultaneously viewing real-time data on cutting speed and feed rate—all displayed on a single screen.

This intuitive design eliminates the need to switch between multiple screens to check progress, allowing operators to easily determine when the required cutting tasks will be completed. The straightforward and easy-to-learn interface boosts operator willingness to engage, ultimately improving production line efficiency and reducing the learning curve.